The adoption of the SMSEagle Hardware SMS Gateway on production lines, by ASK Poland has revolutionized their communication landscape. This versatile device adeptly addresses various communication challenges, underscoring its adaptability through customizable software. The technical support provided by the SMSEagle team garnered praise from Ireneusz Rodak, who lauded their rapid responses and effective solutions.

- Products

- Features

- Full list of features

- Callback URL

- Network monitoring

- Web-GUI

- SMS Forward

- Digital Inputs/Outputs

- Email to SMS

- Periodic SMS

- Shift Management

- Email to SMS Poller

- Autoreply

- LDAP

- SMS to Email

- Failover (HA-cluster)

- Blacklist

- Calls (Voice feature)

- Subscriptions

- Outlook SMS feature

- Escalation

- MMS Support

- MFA

- Temp sensors

- Modem Failover

- Use Cases

- Resources

- Support

- Buy

- Blog

- About us

Effective Alerting in Manufacturing Companies – ASK Poland story

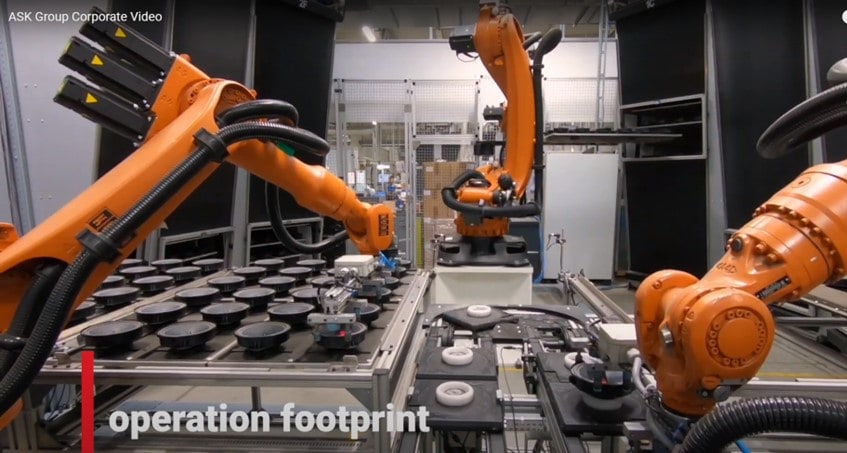

In the world of manufacturing, fast alerting is paramount. ASK Poland, a leading automotive audio producer, faced challenges conveying email alerts to automation engineers. To address this, they adopted SMS notifications for production lines via the SMSEagle Hardware SMS Gateway. This article explores their journey.

ASK POLAND

Company information:

- Location: Poland

- Industry: Motor Vehicle Parts Manufacturing industry.

- Incorporation Date: 1997

- Number of Employees: As of 2020, the company had >900 employees

- Global Presence: In addition to its operations in Poland, ASK has a presence in other countries, including Tunisia and China, indicating its global reach and strategic positioning in various markets

Table of Contents:

- Introduction: ASK Poland’s manufacturing landscape and the need for notification system on their production lines.

- The Challenge: Streamlining Communication on the Production Floor.

- Introducing Quick SMS Alerts on Production Lines: The project to modernize communication.

- Precision in SMS Alert Distribution in ASK factory

- Fine-Tuning Critical Information: Customizing SMS alerts for maximum efficiency.

- A Transformative Communication Experience: The impact of SMS notifications on production lines.

- Looking Ahead: Future plans and the broader applications of the SMSEagle gateway.

ASK Poland was founded in 1997 after more than 30 years of ASK’s existence in Italy as a manufacturer of loudspeakers and electronics for the automotive industry. The company currently employs nearly 900 people in Poland. ASK also operates in Germany, Tunisia, Brazil and China. The Polish branch – ASK Poland, based in Bielsko-Biala, specializes in the production of audio equipment and accessories for the automotive industry. Its offerings include speakers, audio systems, amplifiers and antennas, among others.

To continuously monitor the production lines, ASK Poland relies on the Golem MES system, developed by PPHU Neuron Wojciech Mazurek. This comprehensive system meticulously tracks crucial parameters like machine downtime, productivity, and setup time, ensuring that any deviations are promptly addressed by automation engineers or supervisors. Fast and reliable communication is at the heart of this operation, allowing engineers to minimize disruptions and maintain high production quality.

The Challenge: Streamlining Communication on the Production Floor

For many years, ASK Poland has been refining ways to communicate with engineers about the status of production lines. After the introduction of the Golem MES system, notifications of machine breakdowns and critical changes were sent via e-mail to automation engineers. It quickly became apparent that this method was unreliable; messages were read late because engineers worked on the factory floor – away from their desks.

The need for immediate and effective communication was obvious, given that a finished product leaves the production line every 6 seconds. For this reason, ASK Poland’s requirement for rapid response from engineers necessitated the need to revamp the emergency communication system.

Mr. Ireneusz Rodak, Maintenance Engineer at ASK Poland noted: “Which automation engineer reads e-mails when he is busy repairing a machine on another line? He simply doesn’t have time for that.”

The need for immediate and effective communication was obvious, given that a finished product leaves the production line every 6 seconds. For this reason, ASK Poland’s requirement for rapid response from engineers necessitated the need to revamp the emergency communication system.

Explore SMSEagle demo device for free

Try out over 20 functionalities during free 14-day trial. Get access to our remote device and

discover SMSEagle to leverage your communication.

Introducing Quick SMS Alerts on Production Lines

To bridge the communication gap and reach engineers wherever they may be on the production lines, ASK Poland initiated a project to modernize their communication methods. They sought a solution that could seamlessly integrate with their existing email notification system and ideally reach engineers through their smartphones, devices they always carried. This quest led them to the SMS/MMS SMSEagle hardware SMS gateway, a EU-manufactured solution which can be used as a SMS notification system in factories and production lines, with feature allowing converting email messages into SMS alerts. This unique feature ensured that the same engineers who received email notifications could also access crucial information through SMS alerts right on the production lines.

Opting for the NXS-9750 3G device due to its consistent performance, high throughput for sending SMS messages, and ease of integration, Ireneusz Rodak noted, “Since integrating the SMSEagle Hardware SMS Gateway in August 2019, it has become the cornerstone of our communications on the production floor.”

Precision in SMS Alert Distribution in ASK Factory

The SMSEagle Hardware SMS Gateway has brought structure and hierarchy to communication on the shop floor. Production line workers can now directly communicate problems to their leaders through SMS messages. This system offers flexibility, allowing leaders to change their work location while still receiving calls from workers on the production lines they supervise. Moreover, it can transmit information about machine failures to automakers without any limitations. Currently, 301 machines are part of the factory SMS notification system, but the system’s scalability renders the number almost irrelevant. Workers are automatically deactivated at the end of their shift, and notifications are dispatched only when they are logged into the system.

Golem MES also features an automatic alert system, proficient at independently sending SMS notifications to acousticians or automation engineers responsible for a particular production line when an anomaly is detected.

“The system ensures that whether it is a problem reported manually by line workers or automatically detected by Golem MES, we will immediately notify the right people.“

Ireneusz Rodak

Maitanance Engineer

ASK Poland

Fine-Tuning Critical Information: Customizing SMS alerts for maximum efficiency

The SMSEagle Hardware SMS Gateway empowers ASK Poland to condense email content into a short SMS format. The SMS message commences with the production line’s name, followed by the machine’s name or the worker’s position. This approach enables automation engineers to swiftly ascertain the priority level and the location of the issue on the production lines. This flexibility proves especially valuable when engineers receive notifications on smartwatches. The watch’s vibration signifies that an important message awaits their attention.

Collaborating with SMSEagle’s IT team, ASK Poland customized the Email to SMS Poller to guarantee that alerts deliver the most essential data to their engineers.

A Transformative Communication Experience: The impact of SMS notifications on production lines.

Collaborating with SMSEagle’s IT team, ASK Poland customized the Email to SMS Poller to guarantee that alerts deliver the most essential data to their engineers.

Looking Ahead: Future plans and the broader applications of the SMSEagle gateway.

Regarding future plans, ASK Poland envisions expanding the notification system to encompass more production lines, including semi-automatic ones. Additionally, they contemplate employing the SMSEagle Hardware SMS Gateway device for network monitoring, a task within the purview of their ICT team. This outlook promises a bright future with a more extensive array of applications for the SMS/MMS SMSEagle gateway in manufacturing and production management.

Explore our demo device

SMSEagle is a hardware & software solution that guarantees a swift delivery of your messages to designated recipients, whether it’s for notifications, alerts, or important updates. Discover SMSEagle to stay seamlessly connected.

- 14-days free trial

- Access to over 20 functionalities of the device

Company data

SMSEagle™ brand is owned & manufactured by

Proximus Sp. z o.o.

ul. Piatkowska 163

60-650 Poznan

Poland, EU

Phone: +48 61 6713 413

Contact us

SMSEagle is a professional hardware SMS gateway for sending and receiving SMS messages. The device is designed with focus on reliability and stability. SMS messages are sent/received directly to/from cellular network without using any external 3rd party solutions. The device has a range of built-in plugins that enable additional functionalities and easy to use API for integration with external applications.